THE AUTOMATED HORIZONTAL CARRIER IN ACTION

Thanks to its flexibility, the Autopilot CDI120 pallet carrier can easily be implemented in different applications within your warehouse or logistics center.

It can be integrated into a manual operation or with our Autopilot fleet to operate in a fully automated system.

FROM A TO B

The Autopilot CDI can pick up and transport pallets from point A to B, where for example, an automated stacker will store it in the racking.

The drive-through station allows the automated pallet carrier to efficiently support your point-to-point transport or replenishments, optimizing your logistics flow.

SMART. FLEXIBLE. EFFICIENT.

Autopilot CDI120 offers;

- Personal safety protection

- Small footprint

- Automated charging with lithium-ion battery

...and more. Discover all the model has to offer today!

SAFE OPERATION

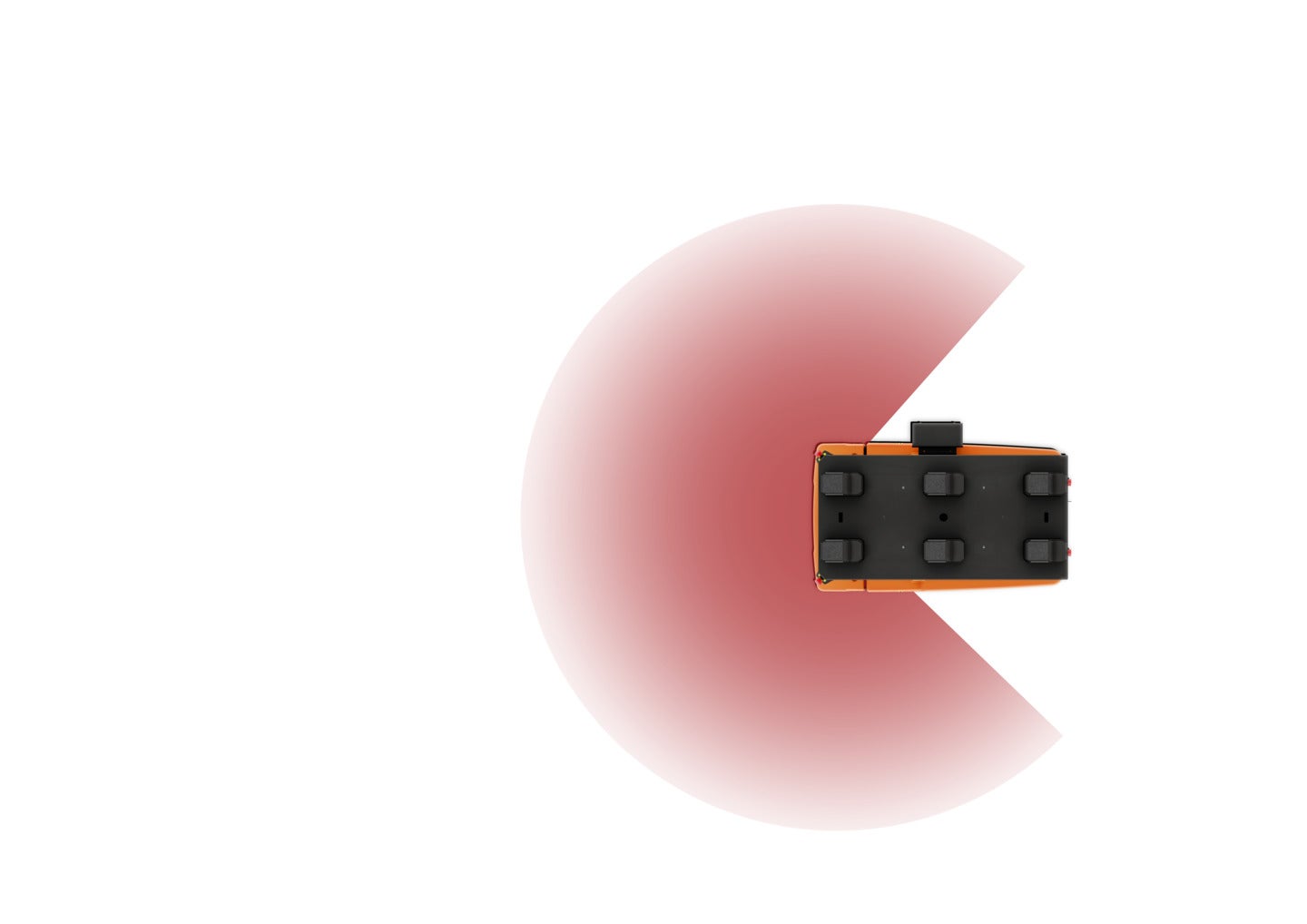

The Autopilot CDI120 is programmed to work alongside manual operators and complete all tasks safely. The built-in safety scanner detects obstacles along its path and takes action to prevent collisions. The automated vehicle is continuously scanning its environment and the safety fields turn towards the driving direction to ensure maximum safety.

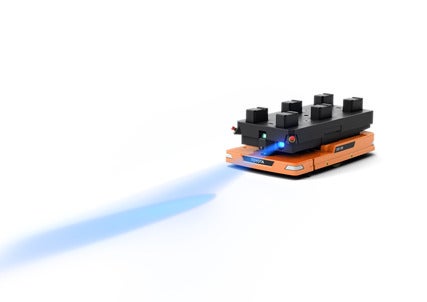

A blue warning light alerts forklift drivers and workers of its presence.

Safety scanner used for safe transportation at rated speed.

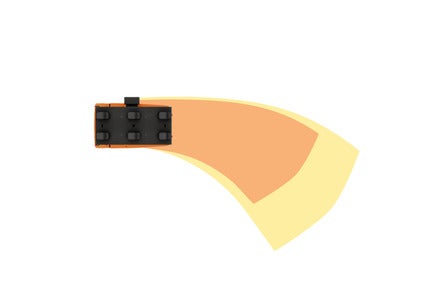

Safety scanner for safe turns at optimum speed.

AGILE MOVEMENTS

The automated horizontal carrier from Toyota is able to move around your logistic center in a very agile way. Thanks to its pick-up and drop-off station, the AGV doesn’t need to reposition or maneuver to access the load; it can just run through. The CDI120 can easily pick up the pallet and continue its journey in one straight line. Another great advantage is that the station can be placed on the floor underneath your racking, optimizing the use of floor space.

In addition, the Autopilot CDI120 is compact and has the ability to turn on point. Combined with the low height, this guided vehicle can work in tight spaces where it is not obvious for other AGVs or manual trucks to operate.

SMART CHARGING

The automated horizontal carrier CDI120 is equipped with lithium-ion batteries that are up to 30% more energy-efficient whilst reducing CO2 emissions. With the ability of auto-charging, including scheduled and opportunity charging options, the AGV can charge quickly between tasks without the need for personnel or charging rooms, making it fully automated.

Flexible localization with natural navigation

The CDI120 has its navigation scanner close to the floor, offering a compact design. It only makes use of natural navigation to find its way into your warehouse. This navigation method utilizes recognizable reference points or landmarks within the warehouse, such as walls, racking, and fixed objects, to calculate the AGV’s location.

The automated pallet carrier can operate via standard natural navigation based on a map with static features and optionally use dynamic natural navigation. In this case, sophisticated software can handle an environment where new features are added. The AGV will learn and memorize the new feature in the process of doing.

Natural navigation is a lower-cost alternative for warehouses where the surroundings remain fairly constant. The AGV can utilize the existing environment to navigate without the need for extra equipment such as reflectors, avoiding extra cost and installation of additional equipment.